At Techso, we understand the crucial role of the Headbox in ensuring the efficient operation of paper machines. Our specialised Headbox repair services are designed to:

- improve performance

- reduce downtime

- extend the life of our customers’ equipment

Our team of experts, whether minor repairs or major overhauls, use state-of-the-art technology and proven techniques to deliver superior results.

Slice Lip and Apron Lip Services

Small damages on the edge parts of the Headbox can cause significant formation problems that affect the paper profile.

To address these issues, Techso begins with a comprehensive survey to identify the root cause of the problem and pinpoint the parts that need to be repaired or replaced.

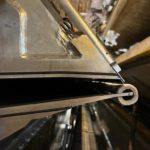

Case Study 1: Slice Lip Damage

In this case, small damages were found on the tip of the slice lip of the Headbox, along with edge damage to the slice lip.

Techso technicians replaced the damaged slice lip, installing a new one manufactured by Techso. This included the installation of edge rubber seals to protect against further edge damage and prevent leakages.

Case Study 2: Apron Lip Damage

In this scenario, issues were identified on the bottom part of the Headbox. The apron lip surface exhibited pitting marks and scratches, with damage in several areas, compromising paper formation. The mill had a spare bottom apron lip, but it was also in poor condition.

Techso first reconditioned the spare apron lip, including welding defect points, tooling, grinding, polishing, and restoring the geometrical dimensions. Subsequently, the apron lip replacement was organized and performed under the supervision of Techso technicians.

Results

As a result, the proper performance of the Headbox was restored. Efficiency was brought back in line with product standards, and formation problems were resolved.

Damaged slice lip.

- Spare apron lip.

- Spare apron lip detected defects.

- Apron lip on tooling machine.