paper

Thanks to the standard we apply and the skills of our engineers we are able to provide high level solutions with a professional project execution.

Techso is able to provide services to support our customers in the following paper grades:

FINE PAPER

PACKAGING GRADES

SPECIALTY PAPER

FINE PAPER

PACKAGING GRADES

SPECIALTY PAPER

Overhauling, maintenance, refurbishing.

Our services for paper machinery

are performed according to the best practise

Stock prep

Polydisks overhaul

Polydisks are fundamental to achieve good machine performances and paper quality. Service engineers inspect and make sure that they reach long lasting runnability. Our services include overhauling and replacement of all parts that may wear out.

Screens overhaul

Screens are fundamental for to achieve good machine performances and paper quality. Service engineers inspect and make sure that they reach long lasting runnability. Our services include overhauling and replacement of all parts that may wear out.

Refiners overhaul

Refiners are fundamental for to achieve good machine performances and paper quality. Service engineers inspect and make sure that they reach long lasting runnability. Our services include overhauling and replacement of all parts that may wear out.

Pulper impeller and gearbox overhaul

Pulpers are fundamental for to achieve good machine performances and paper quality. Service engineers inspect and make sure that they reach long lasting runnability. Our services include overhauling and replacement of all parts that may wear out.

Complete system survey

Complete stock preparation system can be analyzed by TECHSO specialized engineers in order to optimize it implementing more efficient and stable solution and to identify critical points and bottleneck in the process. System is checked from different points of view (process, mechanics, controls) and any recommendation is given to the Customer.

Headbox

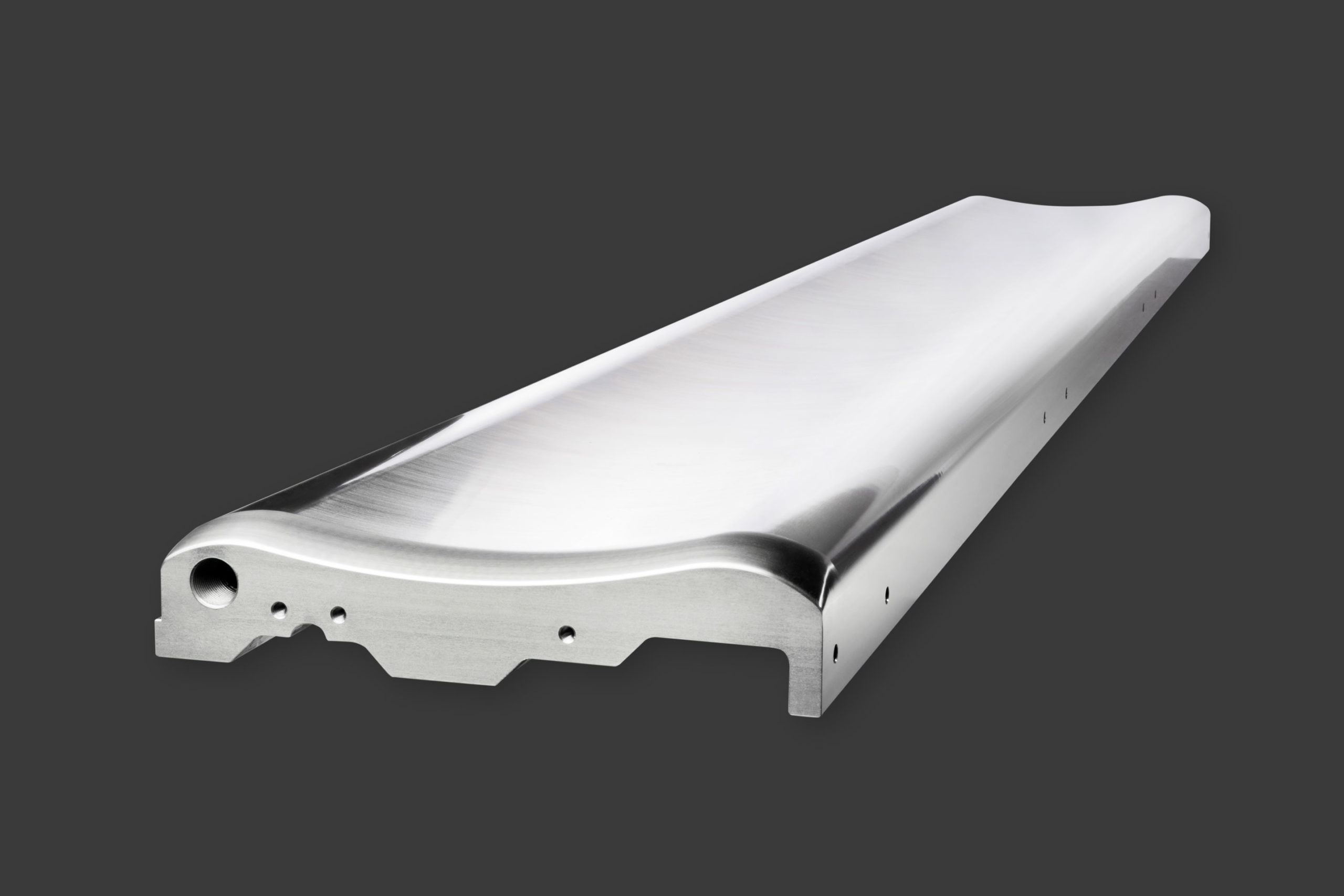

Apron lip replacement

When apron lip gives problem of streaks, formation, profile or fibers buildup on the apron joint must be replaced. TECHSO service engineers are highly experienced to replace it in the most efficient way and in short shut-down.

Apron lip repair (temporary or permanent solution)

If apron lip is locally damaged, TECHSO service engineers can repair it on emergency basis with spot welding and honing of apron nicks, and sharpening of apron tip, restoring original conditions and eliminating streaks and other problems on the paper.

Slice lip replacement and jacks overhaul

When the slice lip tip is worn out and profile cannot be controlled in the proper way, slice lip must be replaced. Jacks must be also overhauled when they cannot guarantee the good profile adjustment.

Overhaul and tuning of headbox jet parameter

All the settings of the headbox (slice opening, setback, tilting) can be checked, adjusted and eventually reset by TECHSO specialized staff as well as the operating parameters (jet/wire ratio, recirculation, etc.).

Pulse attenuator overhaul and tuning

Barring in the sheet, and high frequency MD weight variations are all indications that the headbox attenuator requires a tune-up. A service engineer can analyse the problems and make the required repairs to the attenuator system to bring it back up to peak performance.

Head box survey

Basis weight non-uniformity, streaks, and fiber orientation problems are all symptoms of a headbox that requires a tune-up. Poor formation, skipping, breaks, lumps, streaks, and strings are all the result of poor headbox performance. Service engineers inspect the headbox thoroughly to determine the cause of the poor performance. Recommendations for repairs and improvements are reported to the mill.

Shoe press

Shoe press overhaul

Shoe press is a component that always works under high stress and its efficiency influences the complete process. For that reason periodical maintenance, usually each 2 years, is strongly suggested in order to keep all the components in good conditions. TECHSO offer a service of qualified and well-trained personnel.

Shoe repair and polishing

Accidents on shoe can occur and the result is often the damage of the shoe. If the shoe is scratched, even deeply, TECHSO technicians can repair it directly at mill site by welding and honing, without affecting the straightness of the shoe.

Nip impression

If problems of moisture are detected on the machine, a good way to find the origin is to start from press section loading profile. TECHSO engineers can assist the Customer to do the nip impression and can give recommendations to Customer how to operate to fix the issue.

Shoe press survey

Shoe press efficiency is impacting very much on the complete process efficiency. TECHSO can support the Customer finding critical points on shoe press of any manufacturer. TECHSO technicians can check the shoe press based on the different point of view, technology, mechanics, hydraulics and automation.

Dryer Section

Tail threading system surveys

A properly used threading and rope system can thread a machine quickly and keep mill personnel away from potential danger zones. Service engineers inspect the threading and rope systems throughout the paper machine to insure their safe and proper set-up and operation. General maintenance is completed as required. Recommendations for improvements in operation and safety are reported to the mill.

Max allowable pressure of dryer cans calculation

Old dryer cans are have been usually grinded, so the shell thickness is smaller than original and new calculation of the maximum allowable pressure must be carried out. Same situation is if the shell has been grooved by syphon. TECHSO can directly check the conditions of the cans or do the calculations based on the data from the Customer, if available.

Gear drives overhauling

While geared dryer section are installed, predictive maintenance is very important to avoid unexpected and long shut-down due to problems on the gears. For this reasons predictive maintenance is requested. TECHSO can offer its expertise to the Customer with surveys on the gears system and with service of maintenance and repair of the gears.

Size press

Metering heads maintenance and rebuild

Service personnel inspect the size press for mechanical or operational deficiencies and recommend repairs and improvements such as: clamp, block and bushing replacement, rod holder overhaul, rod drive, etc.

Technological survey

Operational problems with a size press can include the amount of coat weight variation, pickup, uniformity of pickup, sheet wrinkling, threading, breaks, and efficiency. Service personnel inspect the system for mechanical or operational deficiencies and recommend repairs and improvements to correct the problems

Standard maintenance of metering heads

Based on its long experience on metering heads TECHSO suggests overhaul of the critical components periodically and replacements of the main wear parts according the maintenance list. The experienced and qualified TECHSO engineers ensure successful overhaul.

Rolls overhaul

Rolls from both pond and film size press need maintenance and grinding after working period. TECHSO can offer this service, together with a crown analysis and eventual optimization proposal. TECHSO can also provide new rolls complete of cover, bearing, bearing housings, cooling joints, drive chain.

Tail threading system surveys

A properly used threading and rope system can thread a machine quickly and keep mill personnel away from potential danger zones. Service engineers inspect the threading and rope systems throughout the paper machine to ensure their safe and proper set-up and operation. General maintenance is completed as required. Recommendations for improvements in operation and safety are reported to the mill.

Reel

Technological and safety survey

An inspection of the reel framework, rolls, controls, mechanics and technology is conducted as related to machine production, paper quality, maintenance, and safety. Recommendations for improvements and changes are reported to the mill.

Reel maintenance complete with optimization of the movements

Reel performances are connected with the efficiency of the mechanics of the huge number of movements. Reduce the frictions of the movements is a priority. TECHSO service guarantees successful maintenance works and solutions to improve critical situation with qualified field engineers.

Tail threading system surveys

A properly used threading and rope system can thread a machine quickly and keep mill personnel away from potential danger zones. Service engineers inspect the threading and rope systems throughout the paper machine to insure their safe and proper set-up and operation. General maintenance is completed as required. Recommendations for improvements in operation and safety are reported to the mill.

Coaters

Coater heads maintenance and rebuild

Service personnel inspect the coater station for mechanical or operational deficiencies and recommend repairs and improvements such as: clamp, block and bushing replacement, blade holder overhaul, angle and alignment reset, etc. Also orifice plate needs to be straight, and free of nicks or bends. Service engineers, using welding, honing, and straightening techniques can restore the orifice plate to a like new condition.

Technological survey

Operational problems with a coating system can include the amount of coat weight variation, pickup, uniformity of pickup, sheet wrinkling, threading, breaks, and efficiency. Service personnel inspect the system for mechanical or operational deficiencies and recommend repairs and improvements to correct the problems

Standard maintenance of coater heads

Based on its long experience on coater heads TECHSO suggests overhaul of the critical components periodically and replacements of the main wear parts according the maintenance list. The experienced and qualified TECHSO engineers ensure successful overhaul.

Tissue

Yankee bearings replacement

Replacement of the bearings of the Yankee is a very delicate operation to be done safely. Thanks to the long experience TECHSO field engineers ensure high level support and successful shut-down.

Steam system survey

Steam system is the a key part of the tissue machine and influences a lot of parameter. Complete check and survey of the system to optimize the system in order to increase the efficiency, to increase the production and reduce the consumption.

Suction press roll crown optimization

Crown on the suction rolls on the tissue machine is one of the key factors to achieve high quality paper and flat moisture profile. TECHSO can do the calculation of the crown of the suction rolls. Calculation are carried out considering the dynamics of the pressure rolls, the doctors, and the Yankee all together to optimize the pressure roll cover life, doctor blade life, and Yankee cylinder life.

Yankee dryer doctors check and setting

Yankee doctors must be aligned and set-up in perfect way to achieve good paper quality, creping grade and even wear on both blades and dryer shell, that will ensure long last of the surface of the Yankee and few downtime for blades change. Set-up more important action is the profiling of the blade holder. Our service includes all these activities as well as the check of the system by mechanical (static and dynamic) and automation point of view.

Tail threading system surveys

A properly used threading and rope system can thread a machine quickly and keep mill personnel away from potential danger zones. Service engineers inspect the threading and rope systems throughout the paper machine to insure their safe and proper set-up and operation. General maintenance is completed as required. Recommendations for improvements in operation and safety are reported to the mill.

Hydraulic and pneumatic system analysis

Loading and movement hydraulic system analysis

Several key components of the paper machine such as CCRolls and roll loading systems require a properly maintained hydraulic system. Unexpected downtime is the result of poorly maintained systems. Service engineers inspect the hydraulic systems throughout the paper machine to insure their proper set-up and operation. General maintenance is completed as required. Recommendations for improvements are reported to the mill.

Lubrication system analysis

One of the major keys to keeping a paper machine up and running is a properly designed and maintained lubrication system. Service engineers inspect the lubrication units and check out all machine lubrication systems. Recommendations are made to ensure that each lubrication point is receiving the proper oil flow and the system is operating efficiently.

Pneumatic system analysis

Several components of the paper machine operations are done by using air for control of the operations (e.g control valves) or for power (e.g. loading systems). Unexpected downtime is the result of poorly maintained systems. Service engineers inspect the pneumatic systems throughout the paper machine to insure their proper set-up and operation. General maintenance is completed as required. Recommendations for improvements are reported to the mill.

Rolls

Complete variable crown rolls overhaul

An advantage of the deflection crown roll is its long service life. The roll overhaul is focused on the inspection of components critical to roll operation and on extensive safeguarding the operation life. TECHSO service is performed by qualified and well-trained engineers; long expertise in the CBC manufacture and service guarantees the success of the overhaul.

Complete suction rolls (press rolls, couch rolls, pick-up rolls and transfer rolls) overhaul

If for time or for logistic reason revision of suction roll is requested to be done at mill site, TECHSO can guarantee the successful intervention thanks to the long experience in the maintenance of this kind of roll and to experienced and well-trained personnel. The roll overhaul is focused on the inspection of components critical to roll operation and on extensive safeguarding the operation life.

Maintenance on site of any kind of rolls

TECHSO engineers can work for maintenance of special rolls and conventional rolls also at mill site in case of need. Techso engineers can also coordinate teams of workers in order to get best efficiency.

NDT inspections

TECHSO offers NDT inspections for critical positions of the rolls (and in general on any component, when necessary) both in the shop and on mill site. Penetrant test, magnetic test and ultrasonic test with III level qualified personnel can be performed.

Reengineering of critical rolls

Rolls showing issues can be analyzed by Techso technicians and, if improving solution ares available, can be partially or completely reeingineered by Techso.

General services on paper machine

General survey

Surveys on the complete machine are carried out in order to find the bottlenecks of the machine in terms of speed, efficiency or paper defects both on the final product or on the machinery or to explore what are the solution to change productions or implement major rebuilds.

Survey related to components issues

(e.g. stretchers, guides, doctors, showers, rolls and bearings) Survey on the single components are carried out to fix operation problems of the components themselves, to do the fine tuning or to set the component in the default condition or to evaluate eventually the replacement or refurbishment of the components themselves.

Survey related to technological issues

Technological surveys are carried out to improve the quality of the final product or to solve problems on the machinery that are creating problems on the paper. Any recommendation to be reported to the Customer.

Corrosion and cladding survey (present thickness, structural calculation, cladding in site)

Surveys and inspections on stainless steel cladding are conducted to insure its integrity and to reduce, if already there, the propagation of the corrosion even under the cladding. Areas of the machine where corrosion have to be evaluated to see if it is still possible to stop it with repair or if it must be replaced. TECHSO specialist check the conditions and advise the Customer about the proper solution; TECHSO specialized personnel can make necessary repairs.

Dismantling operation supervision for future reassembly

When a part of the machine (or the complete machine) is dismantled and must be recovered to be installed in a different position or mill; TECHSO helps the Customer to make sure that identification, handling, packing and storage are done proper way for easy and safe reinstallation.

Machining and supervision for machining in local shops (boring, key groove)

Service of assistance to works on local shops is done when the work itself must be done locally for time and logistic reasons; TECHSO supervisors can move to the local shop to check and supervise the machining.

Alignment of headbox, rolls, doctors, ceramics

Alignment service is done when paper or clothing are guided out of the central line or after the replacement of any part of the machine or when any uneven wear is found out.

Standard maintenance

TECHSO supports the Customer with the standard maintenance operation with skilled mechanics in all the paper machine areas.