Suitable for board, graphic and coated grades.

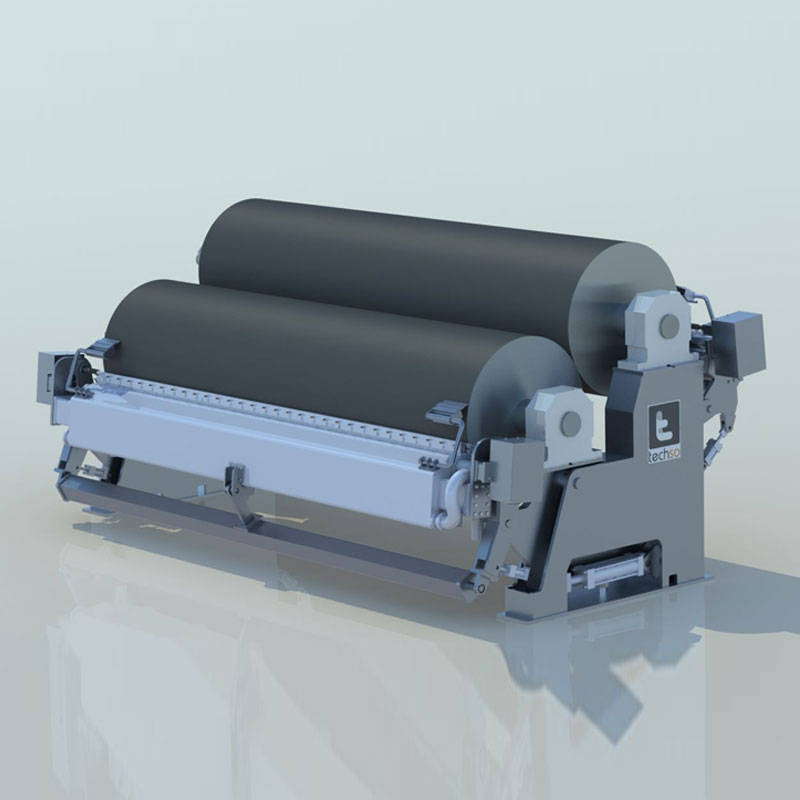

t-SIZE is Techso film size press. As all our products is designed to provide the highest performance with special attention to the maintenance and operations needs. The result is a reliable tool that allow to increase runnability, improves mechanical and printing capabilities reducing overall life cycle cost.

Improves mechanical and printing.

Improves runnability.

Easy to operate.

Robust proven technology.

Reduced maintenance.

Size Press Services

Metering heads maintenance and rebuild

Service personnel inspect the size press for mechanical or operational deficiencies and recommend repairs and improvements such as: clamp, block and bushing replacement, rod holder overhaul, rod drive, etc.

Technological survey

Operational problems with a size press can include the amount of coat weight variation, pickup, uniformity of pickup, sheet wrinkling, threading, breaks, and efficiency. Service personnel inspect the system for mechanical or operational deficiencies and recommend repairs and improvements to correct the problems.

Standard maintenance of metering heads

Based on its long experience on metering heads TECHSO suggests overhaul of the critical components periodically and replacements of the main wear parts according the maintenance list. The experienced and qualified TECHSO engineers ensure successful overhaul.

Rolls overhaul

Rolls from both pond and film size press need maintenance and grinding after working period. TECHSO can offer this service, together with a crown analysis and eventual optimization proposal. TECHSO can also provide new rolls complete of cover, bearing, bearing housings, cooling joints, drive chain.

Tail threading system surveys

A properly used threading and rope system can thread a machine quickly and keep mill personnel away from potential danger zones. Service engineers inspect the threading and rope systems throughout the paper machine to ensure their safe and proper set-up and operation. General maintenance is completed as required. Recommendations for improvements in operation and safety are reported to the mill.